Ras Tanura is a coastal city in the Eastern Province of Saudi Arabia and serves as a major oil operations center and port for Saudi Aramco with a crude distillation capacity of over 500,000* barrels per day.

As a key strategic refinery for Aramco, it was essential that operations were managed efficiently to ensure maximum productivity. However, the facility’s business and operations practices were executed manually or through siloed ad-hoc systems which impacted their overall operations and created multiple issues including:

- Real-time monitoring of refinery operations

- Lack of an integrated solution system between OT and ERP systems

- Prioritization of operational tasks

- Reporting on the health of equipment and maintenance recommendations

- Having automated/semi-automated solutions and notification systems

- Reliable and consistent data

- Engineer’s time inefficiency

- Role based visualization

The Ras Tanura operations teams endeavored to remedy the challenges but realized they ultimately required a single unified approach that incorporated multiple systems to create a unified and integrated solution.

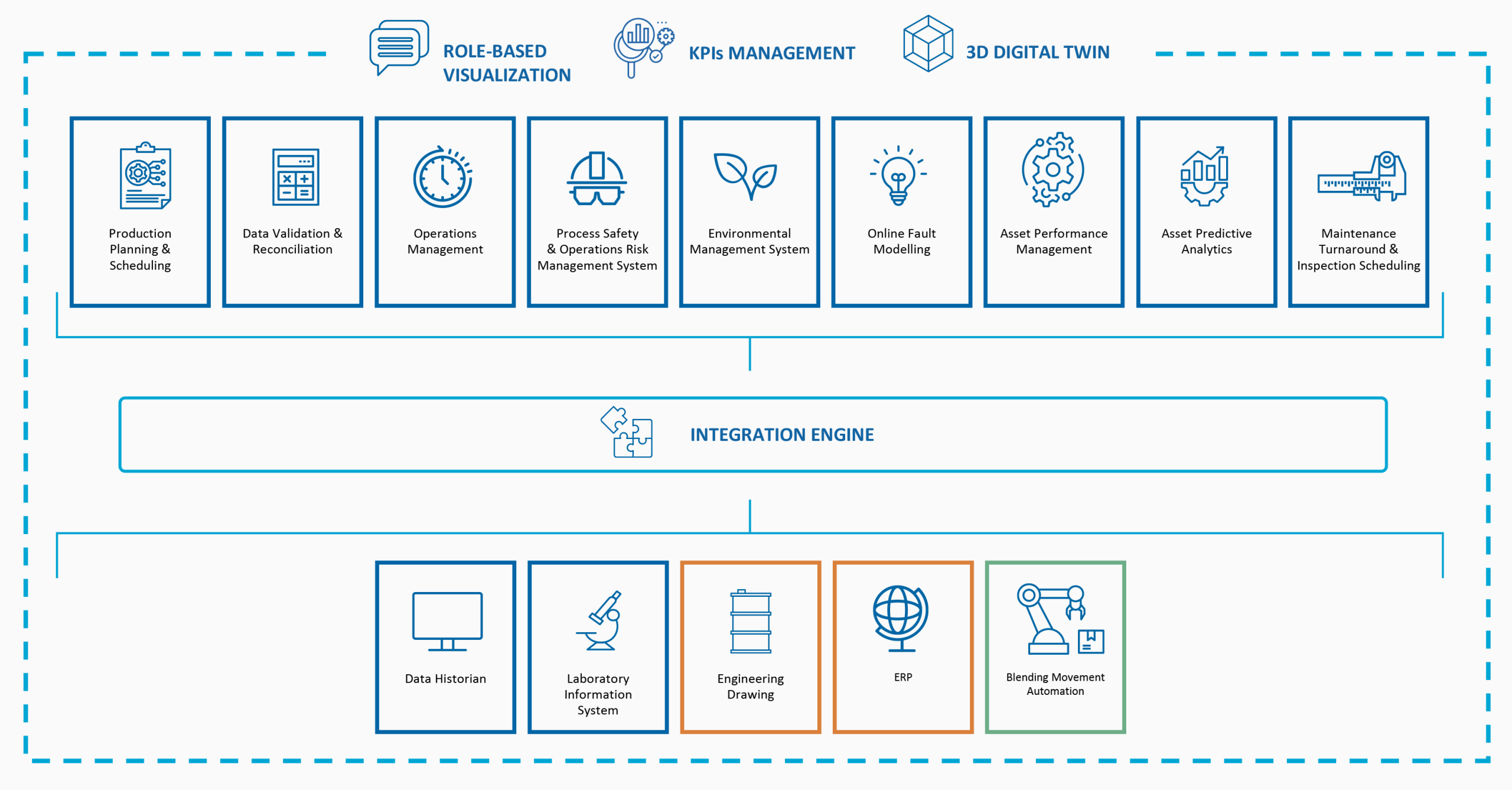

To achieve their goal, the Ras Tanura refinery started working with what is now Plant.Digital’s iMOMS system in 2019 to provide:

- Reliability and Integrity Management: 3D AV, Primavera, Honeywell OFM

- Regulatory Compliance Management: Sphera Essential

- Production Operations Management: HFOM, DVR, Honeywell KPIM

The iMOMS Offered:

Through the implementation of iMOMS, Aramco was able to organize all refinery data from process automation systems and applications through an integrated, real-time framework.

This data transformation ensured Aramco could utilize meaningful and contextualized information to be utilized by employees and applications to drive efficiency, productivity, and safety.

The iMOMS system also helped deliver a range of benefits including:

- Reliable and consistent data

- Critical refinery data obtained efficiently at regular intervals

- Minimize risk of incidents

- Enabling strategic business planning and investment analysis

- Ensuring the right business and operations decision at the right time

- Enabling inventory optimization by converting planned targets to feasible events

The iMOMS system ultimately meant that Aramco could enhance profitability through efficiency and a reduction of operations costs.