Solutions

How We Can Help You

At Plant.Digital, we offer an integrated digital solution suite that aims to provide long-term profitability and productivity improvements in day-to-day operations with a compelling return on investment and time to value for the end user.

How We Innovate

We aim to improve automation by digitalizing workflows and processes via quality, tailored data in a way that’s relevant to you by integrating multiple types of software to aggregate data and translate it into clear information.

The result? Visibility in real-time and unbeatable simulation capabilities that help you make the right decisions every time.

How We Do It

Helping You Innovate

Innovation lives at the core of what we do, and as we build and develop solutions to help

industrial companies thrive, we continue to innovate in various key areas.

Sustainable Strategies

Optimized end-to-end processes are crucial as it enables you to define sustainability strategies and develop a roadmap towards a better future for all.

Reduced Emission & Waste

We deliver solutions that aim to drive sustainability within the industry by reducing emissions, water usage, and waste through information visualization and real-time decision-making.

Leveraging Digital Transformation

We leverage digital solutions to enhance, transform, and improve output and processes through innovative software integration.

Product

Innovation

FAQs

Plant.Digital is formed from two global organizations, Saudi Aramco and Honeywell, that bring their expertise together to create a unique proposition.

The powerful combination of Aramco’s business, operations, technology and delivery expertise, coupled with Honeywell’s proven experience in industrial software and big data analytics solutions, as well as long tenure in the Kingdom, will unlock tremendous value for the industry.

Honeywell and Aramco have partnered for more than 60 years to drive Saudi Arabia’s industrial advancements forward through technology and innovation.

Additionally, the collaboration highlights the commitment of Aramco and Honeywell to Saudi Vision 2030, focused on developing high-tech and knowledge-based careers that add significant value to the Saudi economy to compete globally.

In an ever-evolving industrial world, at Plant.Digital we are transforming and innovating the way in industrial companies think, work, and operate.

We aim to contribute to global innovation by becoming a global industry leader that specializes in implementing, supporting, and optimizing a suite of reliable and highly accessible industrial digital solutions.

Our mission is to provide a reliable, and scalable package of integrated industrial software solutions that reduces cost and improve efficiency, productivity, safety, and sustainability in the long term for industries across the globe.

The future of industrial operations is being able to operate remotely everywhere, simulate everything, and automate anywhere. To make that happen, it’s important to have sustainable digital transformation.

Plant.Digital will leverage Aramco’s technical and domain knowledge combined with Honeywell’s global software development, systems integration and commercialization expertise to develop next-generation digital technology designed to help improve productivity and operational excellence of industrial companies.

Plant.Digital will initially provide services to entities such as Aramco, Aramco joint ventures, and Affiliates, ensuring long- term, reliable partnerships that support and deliver a transformation toward operational excellence, as well as other global Industrial customers.

Plant.Digital will further expand its offering to provide services to the wider petrochemicals industry, water desalination, mining, materials and F&B production using Plant.Digital’s specialized domain knowledge with technology experts focused on innovation, delivery, and dedicated support.

Our initial focus is within the Kingdom of Saudi Arabia and selected Aramco global sites; however, Plant.Digital will expand to provide services to the broader GCC region and ultimately globally.

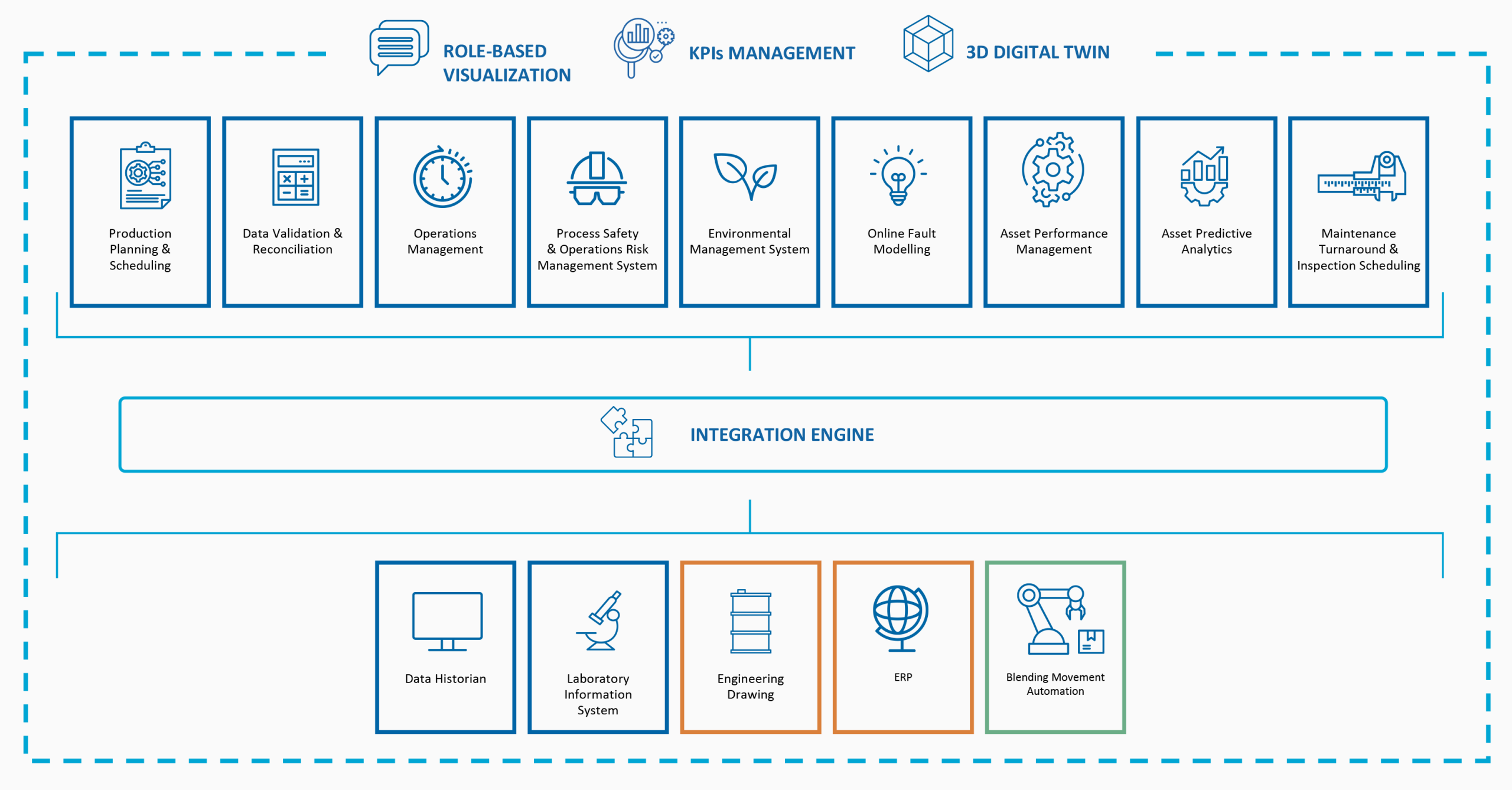

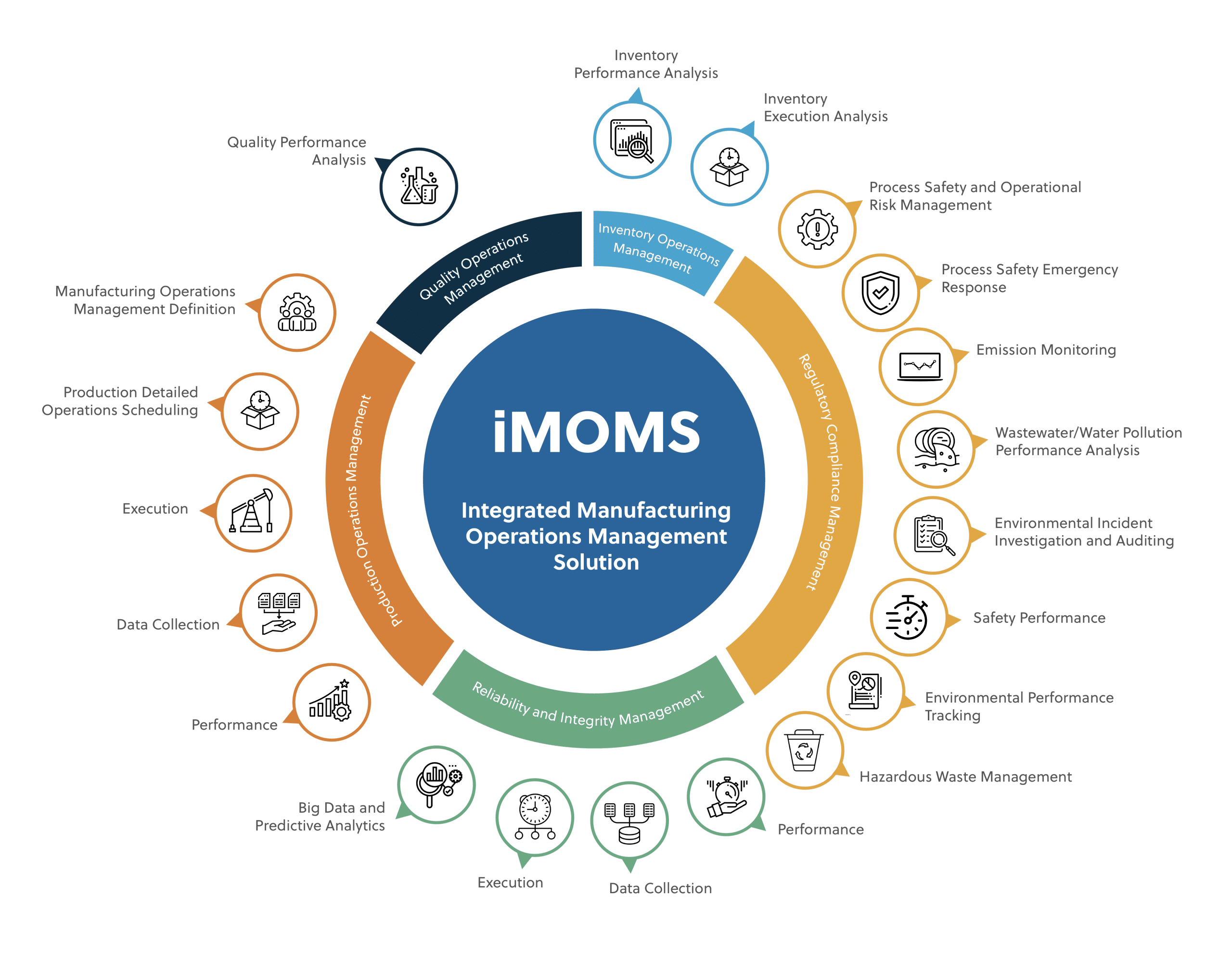

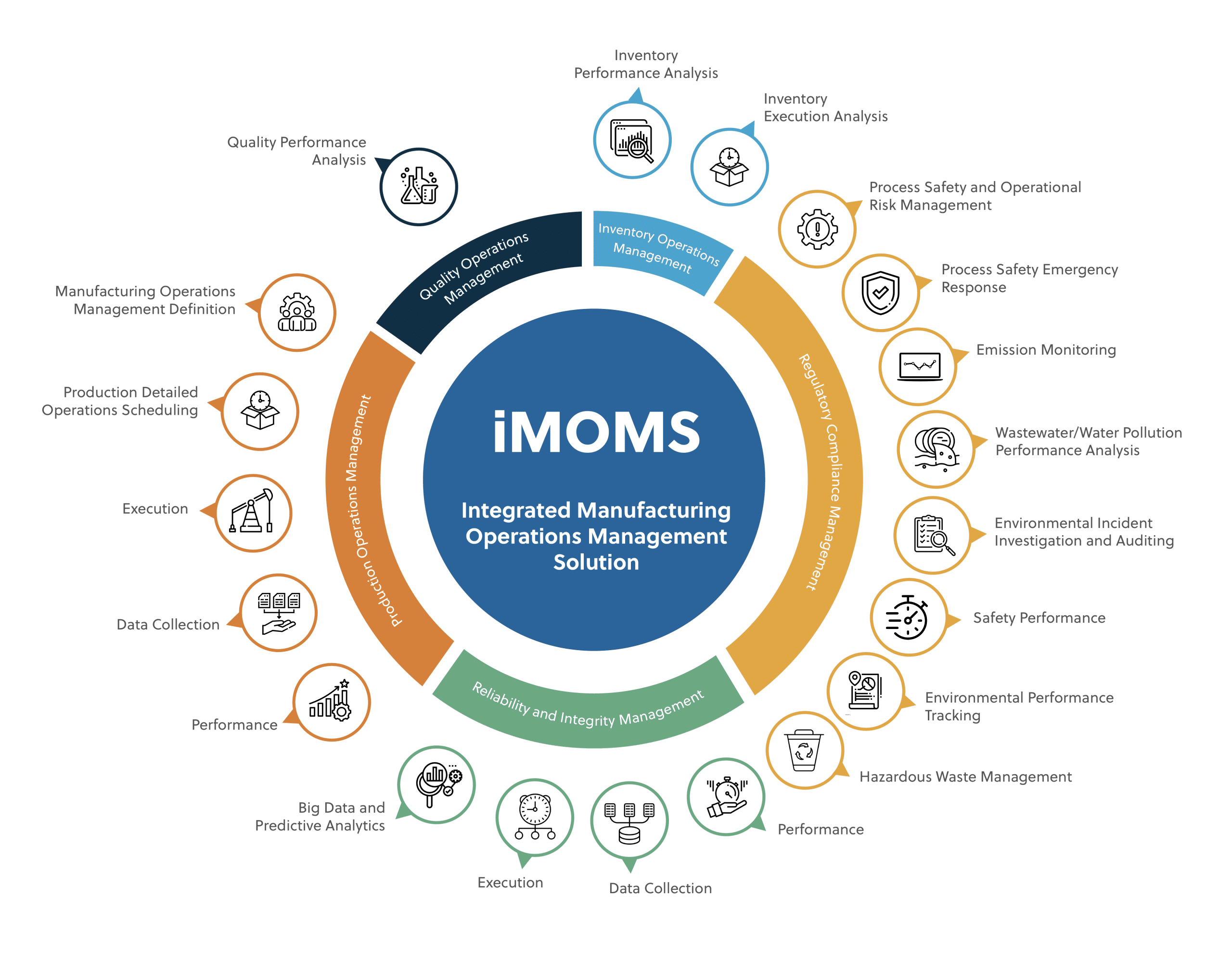

We transform the way industrial companies work. Before Plant.Digital, Distributed Control Systems and Enterprise Resource Planning (ERP) ran operations within industrial companies. The challenge with this approach is that changing any aspect of operations requires an understanding of the financial and productivity impacts which in turn requires data extraction and manual analysis that consumes time and resources. At Plant.Digital, we offer a set of Integrated Manufacturing Operation Management Solutions (iMOMS) that connects Distributed Control Systems to the ERP to provide data in real-time which will help improve plant productivity and ultimately increase profit.

Plant.Digital further innovates the iMOMS suite to allow industrial companies to integrate business and manufacturing data from across the full breadth of plant operations to help maximize yield, reduce downtime and improve

plant productivity and sustainability.

We offer services that are readily available as an on-premise solution that can provide assistance in end-to-end delivery for smart manufacturing solutions:

- Engineering Design and Consulting Services

- System Integration Services

- Application Support Services

- Adoption Management Services

- iMOMS Innovation and Development Services

Through these solutions, we can drive real industrial change for the best, not just in terms of business and economic goals, but in global sustainability overall as well.

Honeywell is a global leader in connected solutions for industry, and helping customers maintain the security of their operational systems is of paramount importance. Implementing safeguards and controls aimed at appropriately managing cybersecurity- related considerations is a fundamental requirement of the new solution that Plant.Digital is delivering.

Plant.Digital is based in Saudi Arabia and is creating more than 500 in-house jobs. We are proudly committed to contributing to Saudi Arabia’s vision by employing local, talented, and entrepreneurial Saudis, and empowering them with leadership and development opportunities to enhance their careers.

As we continue to build Plant.Digital, we are excited to grow a team that drives its success. By employing and empowering young talented men and women from across Saudi Arabia and beyond, we are creating a diverse workforce that aligns with our vision and goals to help innovate businesses and enhance their positions as key industry leaders.

Made in Saudi Arabia but with an international flavor, Plant.Digital offers flexibility and stability as well as a potential career path that could include either of the two major global organizations that are engrained in our foundations. We are a rapidly growing, agile, fast-paced company, with numerous opportunities for growth and the ability to deliver real change.

Plant.Digital will provide more than 500 in-house jobs in Saudi Arabia within five years of its launch, provide a new source of knowledge transfer, support the diversification of the local economy and contribute to KSA’s private sector GDP growth.

The collaboration highlights the commitment of Aramco and Honeywell to Saudi Vision 2030 – the national roadmap to transform the Kingdom into an industrial powerhouse and a global logistics hub.